Strategic Procurement, Data Management, and Reporting Services

We create longstanding partnerships with high volume energy consumers on a global scale, utilizing a client-centric approach to deliver quantifiable value. Our team of energy experts can help market leaders establish customized strategic energy procurement plans, navigate risk and opportunities, and arrive at sustainable supply chain management solutions that best meet the desired objectives.

Have you been procuring your energy with the same provider in the same manner for years? If so, it is time to re-evaluate your approach. Ensure you understand your energy risks and establish customized energy optimization strategies that best fit the risk profile and financial, operational, and sustainability goals of your organization.

The Edison Energy team will conduct a thorough review of your current energy status and provide recommendations on what sustainability services will best support your needs by facility and commodity. Based on those recommendations, we can work with you to develop and implement our supply chain management services across your portfolio or select facilities to help you achieve your organization’s goals.

Evaluate. Refresh. Optimize.

Ensuring you have the right sustainability services performed at the right level at the right time.

Have you been procuring your energy with the same provider in the same manner for years? If so, it is time to re-evaluate your approach. Ensure you understand your energy risks and establish customized energy optimization strategies that best fit the risk profile and financial, operational, and sustainability goals of your organization.

The Edison Energy team will conduct a thorough review of your current energy status and provide recommendations on what sustainability services will best support your needs by facility and commodity. Based on those recommendations, we can work with you to develop and implement our supply chain management services across your portfolio or select facilities to help you achieve your organization’s goals.

Evaluate. Refresh. Optimize.

Ensuring you have the right sustainability services performed at the right level at the right time.

We create customized, comprehensive supply chain sustainability strategies that meet client risk and operational objectives while generating savings. Our team of energy experts uses real-time market intelligence to ensure our clients have the latest and most accurate information to develop energy hedging strategies and make critical energy supply purchasing decisions when it matters most. We pinpoint the best supply chain options for our clients through our competitive bid process. This includes in-depth analysis of each supplier, term, pricing, and product.

Strategize. Optimize. Save.

A partnership that provides peace of mind through accuracy, savings, and risk management.

Features:

- Procurement & Risk Management

- Risk Analysis

- Supply Management

- Demand Response

We create customized, comprehensive supply chain sustainability strategies that meet client risk and operational objectives while generating savings. Our team of energy experts uses real-time market intelligence to ensure our clients have the latest and most accurate information to develop energy hedging strategies and make critical energy supply purchasing decisions when it matters most. We pinpoint the best supply chain options for our clients through our competitive bid process. This includes in-depth analysis of each supplier, term, pricing, and product.

Strategize. Optimize. Save.

A partnership that provides peace of mind through accuracy, savings, and risk management.

Features:

- Procurement & Risk Management

- Risk Analysis

- Supply Management

- Demand Response

Data management is the foundation of every effective supply chain energy strategy. Accurate data you can trust will serve as the building block for all procurement and risk management strategies—not to mention the crucial energy performance reporting that your business will leverage.

At Edison, we not only ensure the accuracy of your data, but we also deliver significant savings and value through our invoice management, energy audit, payment, and reporting services. Whether you manage energy at just a few sites or hundreds, we can handle all of your utility invoices—including water, sewer and energy—to prevent late fees and penalties, and save you time.

Collect. Analyze. Save.

We turn invoice information into usable data that will help identify actionable strategies to save money.

Features

- Invoice Management

- Payments & Audits (invoices)

- Reporting

- Sustainability Reporting

Data management is the foundation of every effective supply chain energy strategy. Accurate data you can trust will serve as the building block for all procurement and risk management strategies—not to mention the crucial energy performance reporting that your business will leverage.

At Edison, we not only ensure the accuracy of your data, but we also deliver significant savings and value through our invoice management, energy audit, payment, and reporting services. Whether you manage energy at just a few sites or hundreds, we can handle all of your utility invoices—including water, sewer and energy—to prevent late fees and penalties, and save you time.

Collect. Analyze. Save.

We turn invoice information into usable data that will help identify actionable strategies to save money.

Features

- Invoice Management

- Payments & Audits (invoices)

- Reporting

- Sustainability Reporting

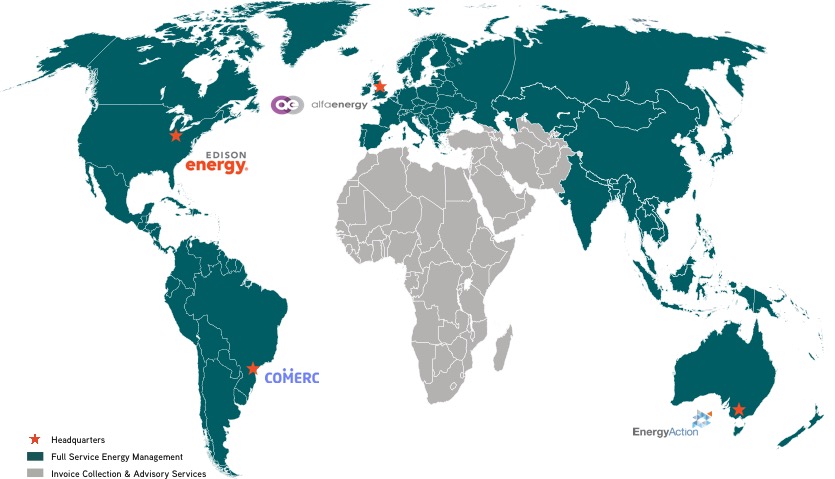

Global Presence

International Reach. Local Expertise.

Edison Energy is a founding member of the Energy Experts Alliance. The four-member Alliance network provides global solutions to meet the energy management and data reporting needs of clients with facilities around the world. We believe it is the ideal business model for providing international account management services coupled with invaluable “home market” expertise from each member of the Alliance. The Alliance covers the following regions: Australasia, Europe, North America and South America. For more information, navigate over to Our Global Presence.

Related Resources

Low Natural Gas Prices Spur a Different Producer Strategy

By Jeff Bolyard, Principal, Energy Supply Advisory

January 2024’s Winter Storm Gerri Brings Flashbacks of Winter Storm Uri

By Jeff Bolyard, Principal, Energy Supply Advisory

Will Mountain Valley Pipeline be the End of Greenfield Interstate Pipelines?

By Jeff Bolyard, Principal, Energy Supply Advisory

A Buyer’s Perspective: Today’s Crude Oil Gain is Tomorrow’s Natural Gas Pain

By Jeff Bolyard, Principal, Energy Supply Advisory

Has Captive Appalachian Natural Gas Production Found an Outlet in the ARCH2 Hydrogen Hub?

By Jeff Bolyard, Principal, Energy Supply Advisory

It’s Complicated: When the Issue of Natural Gas Pricing Isn’t Just About Natural Gas

By Jeff Bolyard, Principal, Energy Supply Advisory